-

Новости

- ECOSYSTEM

- ИССЛЕДОВАТЬ

-

Страницы

-

Группы

-

Мероприятия

-

Статьи пользователей

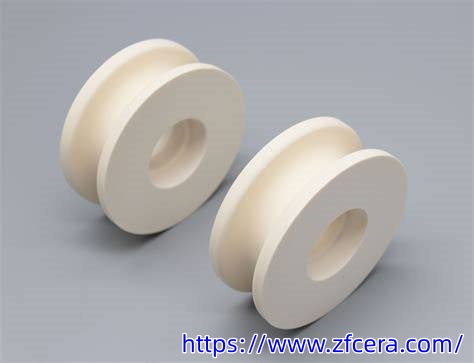

Are Zhufa Alumina Ceramics the Best Choice for High-Temperature Applications?

Alumina ceramics are remarkable for their ability to withstand mechanical wear, high temperature, and chemical exposure. The performance of these components depends heavily on how they are processed—from the initial powder selection to sintering and final finishing. At Zhufa, every alumina ceramic product is carefully engineered to achieve optimal strength, stability, and dimensional consistency for industrial applications.

1. Powder Quality and Preparation

The journey begins with raw materials. The purity, particle size, and distribution of alumina powders determine the density, porosity, and mechanical properties of the final component. Fine powders yield higher density and superior hardness, while uniform particle distribution ensures minimal stress points and structural consistency. The choice of powder directly influences how components behave under thermal cycling and mechanical load.

2. Shaping and Forming Techniques

Once the powders are prepared, shaping techniques define the component geometry and tolerances. Methods such as pressing, extrusion, or injection molding allow precise control over dimensions. Proper forming reduces internal defects and prepares the material for uniform densification during sintering. Components shaped with attention to detail are less prone to cracking, warping, or wear during operation.

3. Sintering and Heat Treatment

Sintering is a critical step where ceramic particles fuse under high temperature to form a dense, durable structure. Parameters such as temperature profile, heating rate, and atmosphere control impact grain growth, porosity, and thermal stability. Well-controlled sintering produces alumina ceramics with enhanced hardness, improved fracture toughness, and minimal shrinkage—ensuring long-term reliability.

4. Finishing and Surface Treatment

Even after sintering, finishing processes play a vital role. Grinding, lapping, or polishing achieve precise dimensions, smooth surfaces, and tight tolerances. Surface quality affects wear resistance, friction, and integration with other components. In some cases, coatings or special treatments enhance chemical resistance or thermal insulation, adding extra value to the final product.

5. Advantages in Industrial Applications

Processed alumina ceramics offer multiple benefits:

Durability: High hardness and wear resistance extend service life.

Thermal Stability: Maintain shape and strength under extreme temperature.

Chemical Resistance: Resist corrosion and degradation in harsh environments.

Precision: Dimensional accuracy ensures compatibility in complex assemblies.

These advantages make alumina ceramics suitable for sectors such as electronics, energy, chemical processing, automation, and mechanical engineering. They are especially critical where reliability and performance cannot be compromised.

6. Integration with Modern Systems

Advanced alumina ceramics seamlessly integrate into high-performance systems. By carefully designing geometry, surface finish, and thermal properties, components become reliable building blocks for critical equipment. Properly processed ceramics reduce maintenance requirements, improve system efficiency, and allow designers to innovate without worrying about material limitations.

7. The Role of Expertise

The expertise behind each component is what differentiates high-quality products from ordinary parts. Precision in every processing stage—powder preparation, forming, sintering, and finishing—ensures that components perform consistently in demanding conditions. Skilled engineering translates material potential into functional reliability, enabling industries to rely on alumina ceramics for their most challenging applications.

8. Future Potential

The continuous development of processing methods opens new possibilities for alumina ceramics. Innovations in shaping, sintering atmospheres, and finishing techniques expand design freedom, reduce weight, and enhance performance. Components now meet standards that were once only achievable with metals, allowing industries to rethink conventional designs and embrace lighter, more efficient solutions.

For engineers and manufacturers seeking high-performance, long-lasting solutions, alumina ceramics provide unmatched reliability. Explore how carefully processed components can elevate your equipment and operational efficiency by visiting https://www.zfcera.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness