-

Noticias Feed

- ECOSYSTEM

- EXPLORE

-

Páginas

-

Grupos

-

Eventos

-

Blogs

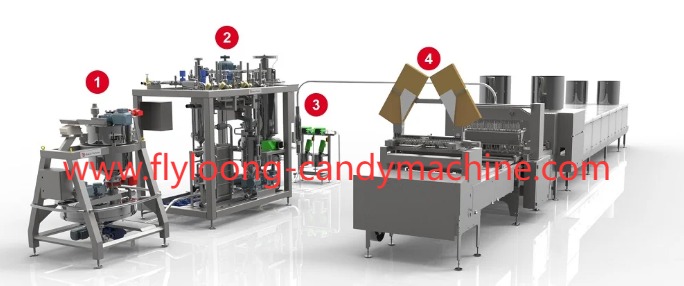

Can Flyloong-candymachine Revolutionize Custom Flat Lollipop Production?

Custom Flat Lollipop Production by Flyloong-candymachine introduces a new era of precision and flexibility in the confectionery industry. This advanced production method allows manufacturers to create uniquely designed flat lollipops that meet diverse consumer preferences while maintaining high-quality standards. With innovation at its core, the process streamlines manufacturing to deliver consistent shapes, flavors, and sizes that appeal to a wide market.

Precision and control are essential in flat lollipop production. Automated systems ensure each candy is crafted to exact specifications, resulting in uniformity that manual processes cannot achieve. This level of accuracy helps reduce waste and increases efficiency, allowing producers to maximize output without sacrificing quality.

Flexibility is another important benefit of modern custom lollipop production. The ability to quickly adjust molds, flavors, and designs enables manufacturers to respond promptly to changing market trends. This agility supports creative freedom and encourages experimentation, helping brands stand out in a competitive confectionery landscape.

Operational efficiency is greatly enhanced through automation. The production line integrates tasks such as mixing, depositing, cooling, and packaging into a seamless workflow. This not only speeds up the entire process but also reduces human error and labor costs. The simplified operation means less downtime and easier maintenance, supporting continuous production cycles.

Maintaining hygiene and safety in candy production is paramount. Automated lines feature enclosed environments and precise temperature controls that safeguard against contamination. These systems comply with stringent food safety regulations, ensuring products are safe for consumers and enhancing brand reputation.

Moreover, the customization aspect of this production method opens doors to niche markets and personalized confectionery options. From seasonal designs to branded giveaways, flat lollipops can be tailored to meet specific promotional or retail needs. This customization drives customer engagement and adds significant value to product offerings.

Investing in modern custom flat lollipop production technology empowers confectionery businesses to innovate and grow sustainably. By improving efficiency, quality, and versatility, manufacturers are better equipped to meet evolving consumer demands and seize new market opportunities.

For those ready to elevate their candy production capabilities, explore the full potential of advanced solutions. Visit https://www.flyloong-candymachine.com/product/ to discover how innovation in custom flat lollipop manufacturing can sweeten your success and open fresh horizons for your business.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness