Key Applications Transforming the Digital Twin Market Landscape

To accurately assess the market landscape and its diverse applications, it is crucial to understand the different classifications of digital twins, as not all virtual models are created equal. A market segmentation analysis of the Digital Twin Market typically categorizes the technology by its level of integration and complexity, most commonly into three distinct types: Product Digital Twins, Process Digital Twins, and System Digital Twins. Each type serves a different purpose and provides a unique level of insight, and their adoption varies by industry and use case. Product Digital Twins are the most common and foundational type, representing a virtual model of a single physical product. These twins are used throughout the entire product lifecycle, from the initial design and simulation phase to real-time monitoring of the product's performance once it is in operation in the field. This granular level of modeling allows companies to test and validate designs virtually, accelerate innovation, and offer new data-driven services based on the operational health of their products, such as "power-by-the-hour" models for jet engines.

Diving deeper into Product Digital Twins, their value is realized across multiple business functions. During the design phase, engineers can use the twin to simulate how a product will perform under various environmental conditions and stress factors, identifying potential design flaws early in the cycle and reducing the reliance on costly physical prototypes. Once the product is manufactured and deployed, IoT sensors on the physical asset feed data back to its digital twin. This allows the manufacturer to monitor the product's health remotely, predict maintenance needs, and provide proactive service to the customer. For example, the digital twin of a medical MRI machine can alert the hospital and the manufacturer to a potential component failure, allowing a technician to be dispatched with the correct part before the machine ever goes offline. The Digital Twin Market size is projected to grow USD 63.41 Billion by 2035, exhibiting a CAGR of 39.3% during the forecast period 2025-2035. This continuous feedback loop from the physical product to its virtual counterpart creates a virtuous cycle of improvement, as the operational data can be used to inform the design of the next generation of products, leading to enhanced reliability and performance over time.

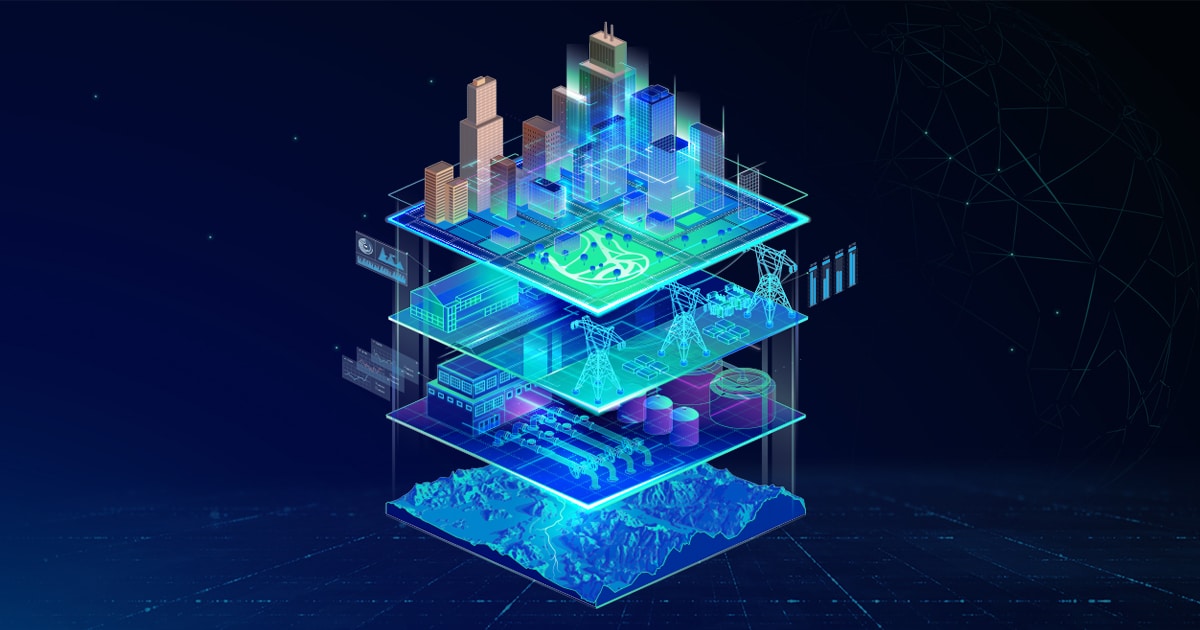

Moving up the complexity scale, Process Digital Twins represent a virtual model of an entire process, such as a manufacturing assembly line, a logistics workflow, or a patient flow process in a hospital. Instead of focusing on a single asset, these twins model the interactions between multiple assets, people, and procedures to optimize the efficiency and output of the overall process. For instance, a digital twin of a bottling plant could be used to simulate the impact of changing the conveyor belt speed or reconfiguring the layout of machines to identify the optimal setup for maximizing production. Finally, System Digital Twins, also known as digital twins of the organization (DTO), are the most comprehensive type. They create a virtual replica of an entire system of interconnected systems, such as a whole factory, a city's transportation network, or a global supply chain. These models provide a holistic, strategic view of complex operations, allowing leaders to understand the cascading effects of decisions and to test large-scale strategies in a virtual environment. The ability to model and optimize at this system level represents the ultimate vision of digital twin technology, enabling unprecedented levels of operational intelligence and resilience.

Top Trending Reports -

School Management System Industry

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness